China Professional 25 Years Manufacturer Multiple Engine/Size Crankshaft Tensioner, Crankshaft Pulley Change Small Size 6D22 Replacement of Many Types of Machine Excavator

Are you in need of high-quality crankshaft tensioners and pulleys for your excavator? Look no further than our 25 years of expertise in manufacturing these essential parts.

Product Description

Our crankshaft tensioners and pulleys are designed to fit multiple engine sizes and models, including the 6D22. You can trust in our high standards of manufacturing to provide reliable replacements for your excavator.

Our product range extends beyond tensioners and pulleys to include steel cover locks, filters, oil grids, pumps, cylinder heads, camshafts, connecting rods, bearings, valves, plunger, nozzles, exhaust valves, engine assemblies, fans, preheaters, radiators, gasket sets, water pumps, turbochargers, generators, starters, and sensors. We specialize in a wide variety of excavator parts.

For factory pricing, shipping information, and discounts, please click the link below to contact us directly.

| ENGINE CUSHION | ||||||||||||||

| NO. | LB NO. | Model | OEM NO. | Name | NO. | LB NO. | Model | OEM NO. | Name | NO. | LB NO. | Model | OEM NO. | Name |

| 1 | KLB-Q3 | BELT TENSIONER | 15 | KLB-Q0017 | SK350-8 4pieces groove | BELT TENSIONER | 28 | KLB-Q0032 | 4BD1 4BG1 A:singlePK B:3PK |

3389198 | CRANKSHAFT PULLEY | |||

| 3 | KLB-Q0003 | 6CT | 3967190 | BELT TENSIONER | 16 | KLB-Q0018 | SK460 3pieces groove | BELT TENSIONER | 29 | KLB-Q0033 | EX200-1/3 6BD1 | CRANKSHAFT PULLEY | ||

| 4 | KLB-Q0004 | EC210 | 462280 | BELT TENSIONER | 17 | KLB-Q0019 | VOLVO360 | BELT TENSIONER | 30 | KLB-Q0034 | 6D31(NEW) | 173*140*34 | CRANKSHAFT PULLEY | |

| 5 | KLB-Q0005 | E325C | 144-1102 | BELT TENSIONER | 18 | KLB-Q571 | S6K | BELT TENSIONER | 31 | KLB-Q0035 | 6D31(OLD) | 160*120*34 | CRANKSHAFT PULLEY | |

| 6 | KLB-Q0006 | PC200-8 | BELT TENSIONER | 19 | KLB-Q0571 | PC60 4D95 | 150*66*43 | CRANKSHAFT PULLEY | 32 | KLB-Q0036 | E200B/320 | 160*113*45 | CRANKSHAFT PULLEY | |

| 7 | KLB-Q0007 | VOLVO210 stainless steel | BELT TENSIONER | 20 | KLB-Q0571 | PC120-6 | CRANKSHAFT PULLEY | 33 | KLB-Q0037 | E320B | 160*110*45 | CRANKSHAFT PULLEY | ||

| 8 | KLB-Q0008 | VOLVO360 | BELT TENSIONER | 21 | KLB-Q571 | PC200-3 6D105 | 144*113*39 6138-31-1480 | CRANKSHAFT PULLEY | 34 | KLB-Q0038 | E320C | 170*143*45 | CRANKSHAFT PULLEY | |

| 9 | KLB-Q0009 | CA016/C7 | BELT TENSIONER | 22 | KLB-Q0571 | PC200-5 6D95 | 150*110*41 6207-31-1410 | CRANKSHAFT PULLEY | 35 | KLB-Q0039 | DH220-5 DB58 | CRANKSHAFT PULLEY | ||

| 10 | KLB-Q571 | VOLVO480 with Belt groove | BELT TENSIONER | 23 | KLB-Q0571 | PC200-6 6D95 | 155*154*42 6209-31-1410 | CRANKSHAFT PULLEY | 36 | KLB-Q0014 | DH | 2107-6004B | BELT TENSIONER | |

| 11 | KLB-Q0011 | VOLVO480 | BELT TENSIONER | 24 | KLB-Q0026 | PC200-6 6D102 | 6735-61-3280 220*54*19 | CRANKSHAFT PULLEY | 37 | KLB-Q0015 | EX | BELT TENSIONER | ||

| 12 | KLB-Q0012 | VOLVO480 | BELT TENSIONER | 25 | KLB-Q571 | PC300-3 PC400 6D125 | 182*118*43 | CRANKSHAFT PULLEY | 38 | KLB-Q571 | EX200-5 6BG1 3pieces groove | 230*120*40 | CRANKSHAFT PULLEY | |

| 13 | KLB-Q0013 | E320C | BELT TENSIONER | 26 | KLB-Q571 | A:PC300-6 6D108 doublePK | 144*127*40 | CRANKSHAFT PULLEY | 39 | KLB-Q0030 | 4D31 | 168*100*35 | CRANKSHAFT PULLEY | |

Frequently Asked Questions

1. What is the brand of your excavator parts?

Our own brand is Mita Group, which includes our line of high-quality crankshaft tensioners and pulleys.

2. Do you have your own factory that we can visit?

Yes, we welcome customers to visit our factory to see our manufacturing processes and products firsthand.

3. How do you ensure the quality of your products?

Our factory holds an ISO9001 certificate, and we strictly control every step of the production process. All of our products are inspected by QC before shipment to ensure they meet our high standards of quality.

4. What is your delivery time?

For ex-stock orders, delivery time is typically 2 to 7 days. For orders that require production, delivery time is typically 15 to 30 days.

5. Can we customize our product packaging with our own company logo?

Yes, we offer customization options for packaging, but a minimum quantity may be required. We also require a Trademark Authorization from customers who wish to use their own branding.

Other Products

In addition to our line of excavator parts, our company also supplies various industrial products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on providing high-quality products, competitive pricing, and excellent customer service. We welcome customers to contact us with their customized drawings and samples.

All the content of this page is from the Internet, and is only meant as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

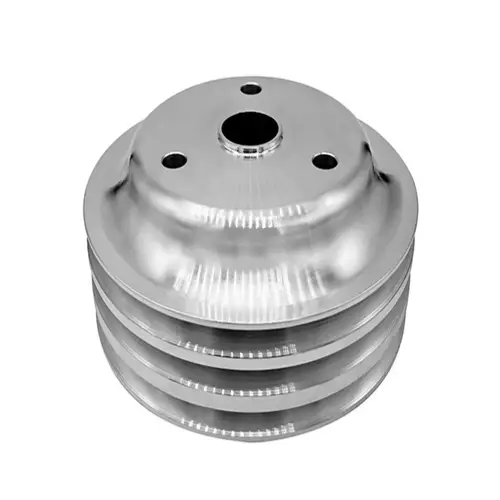

Performance Characteristics of Small Pulley

Small pulleys have several performance characteristics that make them a valuable component in various industries. Firstly, their compact size allows for easy installation and integration into different systems. Secondly, small pulleys offer excellent efficiency and smooth operation, ensuring optimal performance. Additionally, they are known for their durability and long lifespan, providing reliable performance over time. Lastly, small pulleys exhibit low noise and vibration, making them suitable for applications where noise reduction is essential.

Types and Characteristics of Small Pulley

Small pulleys come in various types, each with its own unique characteristics. One common type is the groove pulley, which features a grooved design to accommodate belts or ropes. Another type is the timing pulley, which has teeth that interlock with a timing belt for precise motion control. Additionally, there are V-belt pulleys, which use V-shaped grooves to enhance grip and power transmission. Each type of small pulley offers distinct advantages, suited for specific applications and requirements.

Advantages of Small Pulley Made of Different Materials

Small pulleys can be made from different materials, each offering its own advantages. Steel pulleys, for example, provide exceptional strength and durability, making them suitable for heavy-duty applications. Aluminum pulleys, on the other hand, are lightweight and corrosion-resistant, ideal for applications where weight is a concern. Plastic pulleys offer excellent chemical resistance and low friction, making them suitable for environments that require non-conductive properties. The choice of material for small pulleys depends on the specific needs of the application, ensuring optimal performance and longevity.

Application of Small Pulley in Various Fields

Small pulleys find extensive usage in various industries, highlighting their value and importance. In the medical equipment industry, small pulleys are utilized in precision devices such as medical pumps and surgical robots, ensuring smooth and accurate movement. The automotive industry employs small pulleys in engine systems, power steering, and timing belt mechanisms, contributing to efficient and reliable vehicle operation. Robotics extensively use small pulleys for precise motion control, enabling robots to perform intricate tasks with accuracy. Office equipment, home appliances, and many other fields also benefit from the functionality and versatility of small pulleys.

Future Development Trends and Opportunities for Small Pulley Products

The small pulley industry is poised for continuous growth and development in the coming years. With advancements in technology and increasing demand for automation, small pulleys will continue to play a crucial role in various applications. Additionally, the expansion of industries such as healthcare, automotive, and robotics will further drive the demand for small pulleys. Opportunities for innovation and new product development are abundant, with a focus on enhancing performance, reducing noise, and improving efficiency. As the market evolves, small pulley manufacturers and suppliers should stay proactive and adapt to emerging trends to seize growth opportunities.

Choosing a Suitable Small Pulley

When selecting a small pulley, it is essential to consider several aspects to ensure optimal performance. The load capacity of the pulley should align with the application’s requirements, ensuring it can handle the designated workload. The material of the pulley must be chosen based on factors such as strength, weight, and environmental conditions. Diameter and size play a vital role in compatibility and power transmission, so they should be carefully evaluated. Additionally, considering the type of pulley and bore size is crucial for proper fitting and functionality within the system. By assessing these aspects, one can choose a suitable small pulley that meets the specific needs of the application.

Conclusion

In conclusion, small pulleys offer remarkable performance characteristics, making them a valuable component in various industries. Their compact size, efficiency, durability, and low noise make them an ideal choice for many applications. By understanding the different types and materials of small pulleys, one can harness their advantages for specific requirements. The widespread application of small pulleys in fields such as medical equipment, automotive, robotics, office equipment, and home appliances highlights their significance. As the industry progresses, small pulleys will continue to evolve, presenting new opportunities for growth and innovation. It is crucial to consider factors such as load capacity, material, diameter and size, type of pulley, and bore size when selecting a suitable small pulley. By doing so, optimal performance and compatibility can be achieved, ensuring the smooth operation of the system.

Author: Dream